2025/09/25

Supervisors: Dr. Konstantin Skokov, M.Sc. Allan Döring

Supervisor: Dr. Benedikt Beckmann

2025/07/02

Supervisor: Dr. Benedikt Beckmann

Supervisor: Dr. Pelin Tozman

Open positions for Advanced Research Lab (ARL) and Bachelor/Master thesis or as student assistant (HiWi)

In close collaboration between the Fraunhofer IWKS and the Materials and Resources research group at TU Darmstadt

2024/10/17

Supervisors: Prof. Dr. Anke Weidenkaff , Dr. Songhak Yoon

2022/03/23

Supervisors: Prof. Dr. Anke Weidenkaff , Dr. Wenjie Xie

2022/03/23

Supervisors: Prof. Dr. Anke Weidenkaff , Dr. Wenjie Xie

Supervisor: Prof. Dr. Lambert Alff

Polymer-derived ceramics (PDCs) can be obtained upon pyrolysis of suitable inorganic polymers in inert or reactive atmosphere.[1-3] An important characteristic of PDCs is the strong relationship between the molecular structure and chemistry of the polymers, their processing and the nanostructure and properties of the resulting ceramics.[2] They are nanoscopically heterogeneous and composed of nanodomains. This feature is controlled by the nature and organization of the segregated carbon formed during the polymer-to-ceramic conversion.[2,4,5] Due to their specific features such as tunable electrical, dielectrical, optical and thermal properties, PDCs can act as multifunctional materials performing multiple functions in a system.[1-5]

Supervisors: Dr. rer. nat. Gabriela Mera, Prof. Dr. Ralf Riedel

In response to the changing global landscape, energy has become a primary focus of the major world powers and scientific community. There has been great interest in developing and refining more efficient energy storage devices. One such device, the supercapacitor, has matured significantly over the last decade and emerged with the potential to facilitate major advances in energy storage. Supercapacitors, also known as ultracapacitors or electrochemical capacitors, utilize high surface area electrode materials and thin electrolytic dielectrics to achieve capacitances several orders of magnitude larger than conventional capacitors [1]. In doing so, supercapacitors are able to attain greater energy densities while still maintaining the characteristic high power density of conventional capacitors.

Supervisors: Dr. Magdalena Joanna Graczyk-Zajac, Prof. Dr. Ralf Riedel

2025/09/25

Supervisors: Dr. Konstantin Skokov, M.Sc. Allan Döring

Supervisor: Dr. Pelin Tozman

Supervisor: Dr. Pelin Tozman

Supervisors: Dr. Franziska Scheibel , M.Sc. Allan Döring

Supervisor: Dr. Benedikt Beckmann

2025/07/02

Supervisor: Dr. Benedikt Beckmann

Supervisor: Dr. Pelin Tozman

2025/04/04

Supervisors: M.Sc. Johannes Puy, Dr. Franziska Scheibel

Hybrid perovskite: Structural prototypes and DFT

Research Group Theory of Magnetic Materials (TMM)

2025/04/01

Hybrid perovskites have attracted considerable interest recently for their exceptional optoelectronic properties and potential applications in photovoltaics, light-emitting devices, and photodetectors, making them highly promising for next-generation technologies. In this project, AiiDA workflow manager and VASP will be used to conduct high-throughput calculations to identify stable and high-performance two-dimensional (2D) perovskites.

This research focuses on the generation of 2D perovskite structures across different structural prototypes, including Ruddlesden-Popper (RP) and Dion-Jacobson (DJ) phases. The primary objective of this project is to investigate physical properties, such as shift current, in screened perovskite candidates. Consequently, this project necessitates a strong motivation to work with various tools, including AiiDA, VASP, Wannier90, and Python.

Please write to Prof. Hongbin Zhang (Email: hzhang@tmm.tu-darmstadt.de) if you are interested.

Supervisor: Prof. Dr. Hongbin Zhang

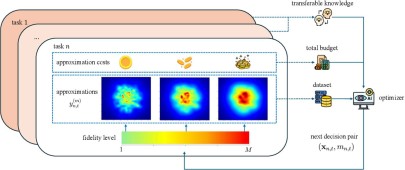

Implementation of Multi-Fidelity Bayesian Optimization with Consideration of Costs

Research Group Theory of Magnetic Materials (TMM)

2025/04/01

Optimizing the performance and parameters of complex systems is a challenging task in modern engineering and scientific research, especially when data acquisition is costly or of variable quality. Multi-fidelity Bayesian optimization (MFBO) is capable of integrating data with different fidelity (i.e., varying accuracy and cost) to improve the efficiency and reduce the total cost of the optimization process.

The aim of this study is to implement a multi-fidelity Bayesian optimization framework that takes into account the cost of data to improve the optimization performance under resource constrained conditions.

Supervisor: Prof. Dr. Hongbin Zhang

Generative diffusion model for crystal structures

Research Group Theory of Magnetic Materials (TMM)

2025/04/01

In this project, we are going to focus on establishing a methodology to leverage advanced machine learning techniques, particularly deep generative models, to predict novel inorganic material compositions. The model will be trained on a large dataset of computational inorganic materials, learning the underlying distribution and optimizing the relevant physical properties in the properly constructed latent space. Once trained, the model can propose new, valid inorganic compositions that are likely to exhibit desirable properties.

Expertise will be gained in the generative diffusion model as specified in https://arxiv.org/abs/2312.03687, and coding with Python valuable for both future PhD studies and industrial positions.

Supervisor: Prof. Dr. Hongbin Zhang

2024/10/28

Supervisors: Dr. Imants Dirba, M.Sc. Latif Durgun

Advanced Research Lab / Master’s Student

NdFeB magnets

2024/10/28

Supervisors: M.Sc. Latif Durgun, Dr. Imants Dirba

Open positions for Advanced Research Lab (ARL) and Bachelor/Master thesis or as student assistant (HiWi)

In close collaboration between the Fraunhofer IWKS and the Materials and Resources research group at TU Darmstadt

2024/10/17

Supervisors: Prof. Dr. Anke Weidenkaff , Dr. Songhak Yoon

Supervisors: Dr. Xingxing Xiao, Dr. Marc Widenmeyer

Supervisors: Dr. Xingxing Xiao, Prof. Dr. Anke Weidenkaff

2022/03/23

Supervisors: Prof. Dr. Anke Weidenkaff , Dr. Wenjie Xie

2022/03/23

Supervisors: Prof. Dr. Anke Weidenkaff , Dr. Wenjie Xie

Supervisor: Prof. Dr. Lambert Alff

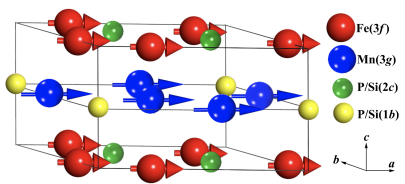

High throughput Design of Fe2P-type Magneto-caloric Materials

Research Group Theory of Magnetic Materials (TMM)

2021/03/30

Supervisor: Prof. Dr. Hongbin Zhang

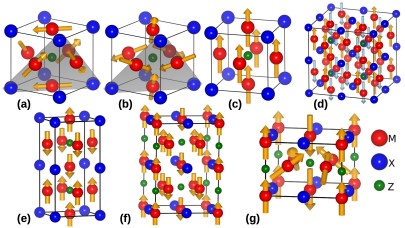

High throughput Screening of Magnetic Ground States

Research Group Theory of Magnetic Materials (TMM)

2021/03/30

Supervisor: Prof. Dr. Hongbin Zhang

Topological Phenomena in Kagome Magnets

Research Group Theory of Magnetic Materials (TMM)

2021/03/30

Supervisor: Prof. Dr. Hongbin Zhang

Designing permanent magnets by interstitial and substitutional doping

Research Group Theory of Magnetic Materials (TMM)

2021/02/02

In this project massive density functional theory calculations should be carried out to evaluate the thermal conductivities for both 2D and 3D insulators with large band gaps. Particular focus should hereby be on those cases with tunable structural phase transitions.

If time allows there will also be explorative calculations to get the interfacial thermal resistance.

Supervisor: Prof. Dr. Hongbin Zhang

High throughput design of 2D functional van der Waals Materials

Research Group Theory of Magnetic Materials (TMM)

2020/09/02

Supervisor: Prof. Dr. Hongbin Zhang

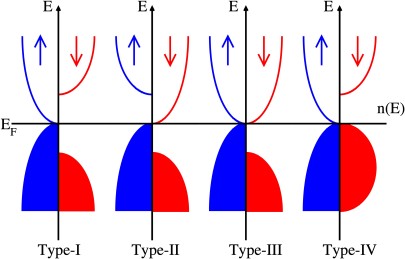

High throughput screening for 3D and 2D spin-gapless semiconductors

Research Group Theory of Magnetic Materials (TMM)

2020/07/02

Supervisor: Prof. Dr. Hongbin Zhang

Polymer-derived ceramics (PDCs) can be obtained upon pyrolysis of suitable inorganic polymers in inert or reactive atmosphere.[1-3] An important characteristic of PDCs is the strong relationship between the molecular structure and chemistry of the polymers, their processing and the nanostructure and properties of the resulting ceramics.[2] They are nanoscopically heterogeneous and composed of nanodomains. This feature is controlled by the nature and organization of the segregated carbon formed during the polymer-to-ceramic conversion.[2,4,5] Due to their specific features such as tunable electrical, dielectrical, optical and thermal properties, PDCs can act as multifunctional materials performing multiple functions in a system.[1-5]

Supervisors: Dr. rer. nat. Gabriela Mera, Prof. Dr. Ralf Riedel

The topic to be addressed will involve the preparation of functional ceramics from tailored polymeric single-source precursors. The research work is closely linked to a scientific cooperation with the company Merck KGaA in Darmstadt.

Supervisors: Prof. Dr. Ralf Riedel, Dr. Ying Zhan

2025/09/25

Supervisors: Dr. Konstantin Skokov, M.Sc. Allan Döring

Supervisor: Dr. Pelin Tozman

Supervisor: Dr. Pelin Tozman

Supervisors: Dr. Franziska Scheibel , M.Sc. Allan Döring

Cutting-edge Research on Next-Generation Sodium batteries

Are you passionate about energy storage and materials science? Have you ever seen the processes in batteries in reality and understood why they operate/fail?

2025/07/04

Join our cutting-edge research on anode-free solid-state sodium batteries (AFSSBs) — a breakthrough technology that combines high energy density, safety, and sustainability.

In this project, you’ll have the unique opportunity to directly observe the dynamic behavior of sodium metal during battery operation using in-situ EM. This powerful technique lets you witness, in real time, how sodium filaments grow and interact with engineered interfaces.

Ideal for Master’s students in materials science, chemical engineering, physics, or related fields.

Be part of the next wave of battery innovation — apply now!

Supervisor: Prof. Dr. Christian Kübel

Supervisor: Dr. Benedikt Beckmann

2025/07/02

Supervisor: Dr. Benedikt Beckmann

2025/06/05

Supervisors: Dr. Lukas Schäfer, Dr. Imants Dirba

Supervisor: Dr. Pelin Tozman

2025/04/04

Supervisors: M.Sc. Johannes Puy, Dr. Franziska Scheibel

2025/04/01

Hybrid perovskite: Structural prototypes and DFT

Research Group Theory of Magnetic Materials (TMM)

2025/04/01

Hybrid perovskites have attracted considerable interest recently for their exceptional optoelectronic properties and potential applications in photovoltaics, light-emitting devices, and photodetectors, making them highly promising for next-generation technologies. In this project, AiiDA workflow manager and VASP will be used to conduct high-throughput calculations to identify stable and high-performance two-dimensional (2D) perovskites.

This research focuses on the generation of 2D perovskite structures across different structural prototypes, including Ruddlesden-Popper (RP) and Dion-Jacobson (DJ) phases. The primary objective of this project is to investigate physical properties, such as shift current, in screened perovskite candidates. Consequently, this project necessitates a strong motivation to work with various tools, including AiiDA, VASP, Wannier90, and Python.

Please write to Prof. Hongbin Zhang (Email: hzhang@tmm.tu-darmstadt.de) if you are interested.

Supervisor: Prof. Dr. Hongbin Zhang

Implementation of Multi-Fidelity Bayesian Optimization with Consideration of Costs

Research Group Theory of Magnetic Materials (TMM)

2025/04/01

Optimizing the performance and parameters of complex systems is a challenging task in modern engineering and scientific research, especially when data acquisition is costly or of variable quality. Multi-fidelity Bayesian optimization (MFBO) is capable of integrating data with different fidelity (i.e., varying accuracy and cost) to improve the efficiency and reduce the total cost of the optimization process.

The aim of this study is to implement a multi-fidelity Bayesian optimization framework that takes into account the cost of data to improve the optimization performance under resource constrained conditions.

Supervisor: Prof. Dr. Hongbin Zhang

Generative diffusion model for crystal structures

Research Group Theory of Magnetic Materials (TMM)

2025/04/01

In this project, we are going to focus on establishing a methodology to leverage advanced machine learning techniques, particularly deep generative models, to predict novel inorganic material compositions. The model will be trained on a large dataset of computational inorganic materials, learning the underlying distribution and optimizing the relevant physical properties in the properly constructed latent space. Once trained, the model can propose new, valid inorganic compositions that are likely to exhibit desirable properties.

Expertise will be gained in the generative diffusion model as specified in https://arxiv.org/abs/2312.03687, and coding with Python valuable for both future PhD studies and industrial positions.

Supervisor: Prof. Dr. Hongbin Zhang

2024/10/28

Supervisors: Dr. Imants Dirba, M.Sc. Latif Durgun

Advanced Research Lab / Master’s Student

NdFeB magnets

2024/10/28

Supervisors: M.Sc. Latif Durgun, Dr. Imants Dirba

Open positions for Advanced Research Lab (ARL) and Bachelor/Master thesis or as student assistant (HiWi)

In close collaboration between the Fraunhofer IWKS and the Materials and Resources research group at TU Darmstadt

2024/10/17

Supervisors: Prof. Dr. Anke Weidenkaff , Dr. Songhak Yoon

Supervisors: Dr. Xingxing Xiao, Dr. Marc Widenmeyer

Supervisors: Dr. Xingxing Xiao, Prof. Dr. Anke Weidenkaff

2022/03/23

Supervisors: Prof. Dr. Anke Weidenkaff , Dr. Wenjie Xie

2022/03/23

Supervisors: Prof. Dr. Anke Weidenkaff , Dr. Wenjie Xie

Supervisor: Prof. Dr. Lambert Alff

High throughput Design of Fe2P-type Magneto-caloric Materials

Research Group Theory of Magnetic Materials (TMM)

2021/03/30

Supervisor: Prof. Dr. Hongbin Zhang

High throughput Screening of Magnetic Ground States

Research Group Theory of Magnetic Materials (TMM)

2021/03/30

Supervisor: Prof. Dr. Hongbin Zhang

Topological Phenomena in Kagome Magnets

Research Group Theory of Magnetic Materials (TMM)

2021/03/30

Supervisor: Prof. Dr. Hongbin Zhang

Designing permanent magnets by interstitial and substitutional doping

Research Group Theory of Magnetic Materials (TMM)

2021/02/02

In this project massive density functional theory calculations should be carried out to evaluate the thermal conductivities for both 2D and 3D insulators with large band gaps. Particular focus should hereby be on those cases with tunable structural phase transitions.

If time allows there will also be explorative calculations to get the interfacial thermal resistance.

Supervisor: Prof. Dr. Hongbin Zhang

High throughput design of 2D functional van der Waals Materials

Research Group Theory of Magnetic Materials (TMM)

2020/09/02

Supervisor: Prof. Dr. Hongbin Zhang

High throughput screening for 3D and 2D spin-gapless semiconductors

Research Group Theory of Magnetic Materials (TMM)

2020/07/02

Supervisor: Prof. Dr. Hongbin Zhang

Polymer-derived ceramics (PDCs) can be obtained upon pyrolysis of suitable inorganic polymers in inert or reactive atmosphere.[1-3] An important characteristic of PDCs is the strong relationship between the molecular structure and chemistry of the polymers, their processing and the nanostructure and properties of the resulting ceramics.[2] They are nanoscopically heterogeneous and composed of nanodomains. This feature is controlled by the nature and organization of the segregated carbon formed during the polymer-to-ceramic conversion.[2,4,5] Due to their specific features such as tunable electrical, dielectrical, optical and thermal properties, PDCs can act as multifunctional materials performing multiple functions in a system.[1-5]

Supervisors: Dr. rer. nat. Gabriela Mera, Prof. Dr. Ralf Riedel

![Figure 1. SiCN PDC produced by the pyrolysis of a graphene-polysilazane at 1100°C in Ar atmosphere.[5]](/media/mr/df_webseite/responsive_2/stellenangebote_2/SiCN-PDC_405x0.png)