Our Approach

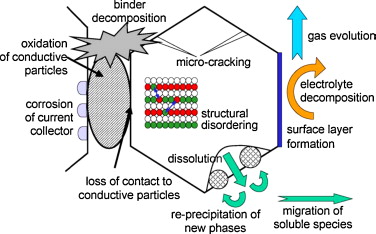

Our research in the field of batteries focus on the following questions: What causes batteries to store less energy over time? Why is there no electric car with a range of 900 km instead of 450 km? How can a battery be made safer? To answer these questions, we need to combine our knowledge of materials science, electrochemistry, and physics of surfaces. Unfortunately, more questions arise. Can we calculate the half-cell potential from material properties? Are the electrolyte and electrode really stable? Why does the voltage of a lithium-ion battery change under discharging? To get answers to all these questions, we are investigating novel cathodes (with less cobalt), high-energy cathodes and new solid-state electrolytes. We combine XPS and electrochemistry to reveal changes in the electronic band structure. For this purpose, we build both laboratory cells and thin-film batteries to bridge the gap between fundamental research and application.

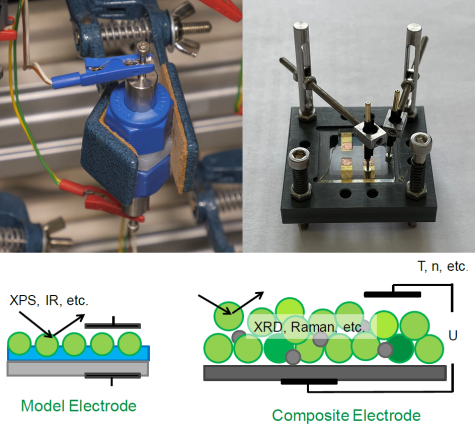

- From particles to thin films: In large scale Li-ion batteries, cathode material is a composite consisting of binder and conductive carbon. To study the intrinsic properties of cathode material, we simplify the battery system by excluding influences like roughness, porosity and effects of binder and other components.

- Quasi in situ: battery material properties are strongly dependent on the state of charge. With stepwise charging/discharging and XPS-measurements we are looking for the correlation between XPS-data and electrochemistry data.

- Novel materials: With a profound knowledge of LiCoO2, we go to the advanced cathode materials like NMC333, NMC622, NMC811 and Mn-rich cathodes. We also look for new solid electrolytes, which are stable with lithium metal.

- Fundamental understanding: The fundamental electrochemical properties are deeply connected with the electronic band structure of the materials. With measuring work functions, valence band maximum and ionic work function, calculation of the absolute potential of the cathode material is possible.

Recent Highlights

-

![]()

![]()

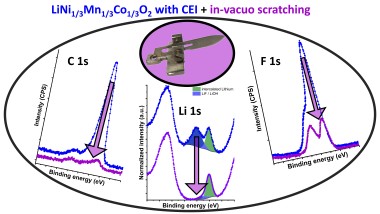

Publication on In vacuo scratching yields undisturbed insight into the bulk of lithium-ion battery positive electrode materials

2024/09/20

Now online

Mellin et. al introduce the method of in vacuo scratching as preparation for XPS measurements of LIB positive electrode materials, which can drastically reduce spectral contaminations and enhance spectral quality, enabling higher information gain.

-

New DFG Project 'NSERC-DFG SUSTAIN' granted

2023/08/14

As part of a German-Canadian call on sustainability, we will soon be launching the consortium project 'NSERC-DFG SUSTAIN: Carbon materials from oil sands-based asphaltenes for future sodium batteries – from mechanistic studies to life cycle analysis'. We are working together with the group of Prof. Martin Oschatz from the Friedrich Schiller University Jena and the groups of Prof. Weixing Chen and Prof. Amit Kumar from the University of Alberta in Edmonton, Canada, on novel anode materials for sodium ion batteries. The Surface Science Lab will deal with fundamental aspects of materials characterization and the investigation of sodium storage mechanisms.

Current Projects

-

![]()

![]()

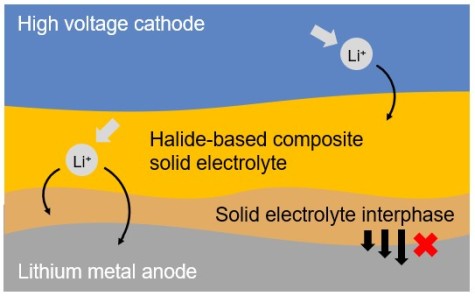

Anode and Cathode Interfaces with Halide-based Solied Electrolyte

2024/01/01

Interface analysis between halide-based composite solid electrolyte with lithium metal anode and high voltage cathode

The stability in batteries is dictated by the interfaces of the electrolyte and the electrodes.

-

![]()

![]()

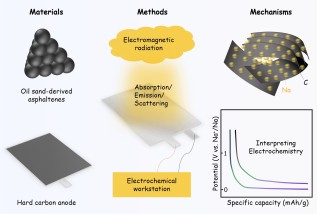

NSERC-DFG SUSTAIN – Project OILSANDBATT

2023/09/01

Carbon materials from oil sands-derived asphaltenes for next-generation sodium-ion batteries – from mechanistic investigations to life cycle analysis

Lithium-ion batteries (LIBs) dominate energy storage, but rising lithium demand and environmental concerns drive research into sodium-ion batteries (SIBs). Germany aims to advance eco-friendly SIB technology, focusing on cost-effective materials. Asphaltenes, abundant oil sands by-products in Canada, offer a low-cost alternative but are largely wasted