Signposts for tiny lightning strikes

Memory chips for the next computer generations

2020/03/25 by Christian J. Meier

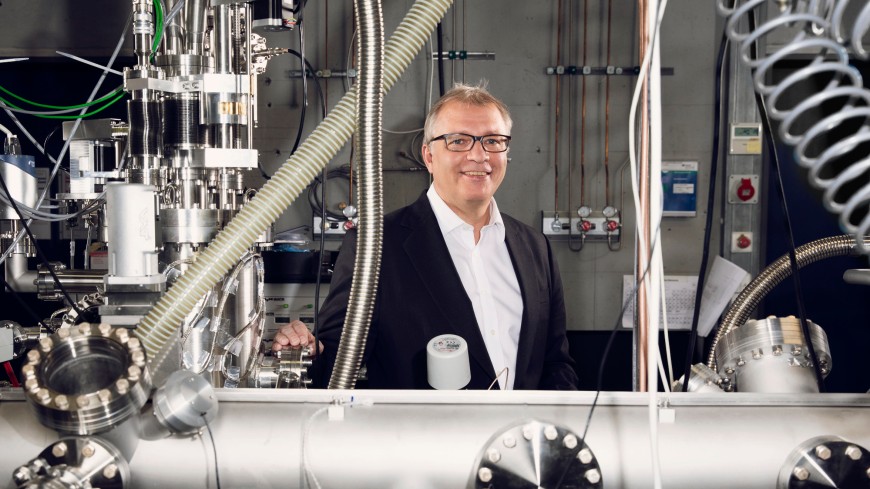

Researchers in Darmstadt around materials scientists Professor Lambert Alff and Professor Leopoldo Molina-Luna are developing memory devices for a new type of chip.

Lambert Alff controls lightning bolts, although only on a microscopically small scale. The professor aims to use these discharges to produce memory devices for computers that can also process data at the same time. “This is the next revolution in computer technology”, says Alff. He recently made and published an important contribution to this research with his team in the Materials Science Faculty at TU Darmstadt, in cooperation with the group headed by Professor Leopoldo Molina-Luna who are carrying out research just a few doors down the corridor.

What does the materials scientist mean when he talks of a revolution? The “Internet of Things” is becoming more tangible every day. An increasing number of everyday objects contain small computers and these smart objects now often transmit the data to the cloud where it is processed. This transmission process requires energy. In addition, processors need to be constantly supplied with energy because otherwise they will lose data. “In twenty years’ time, the IT sector alone will require as much energy as is consumed today in total around the world unless we develop something new”, warns Alff.

Alff has a clear vision of what this new development will look like: Nonvolatile memory modules that can also process data at the same time. After being switched off, the chip will save its current status like a paused film and continue to process the data as soon as the power supply is restored. “A smartwatch could thus record jogging data and also process it by itself”, says Alff. The researchers in Darmstadt had an eye on the future application of this technology from the very beginning, which is why they are developing their components based on hafnium oxide, a material that is already used in the production of chips today. The team uses tiny crystals of this substance that are smaller than a virus. The crystals do not conduct electricity. However, if you apply an increasing amount of voltage to them, there is eventually a discharge: A channel opens up in the crystal, through which electrical charge can now flow. This channel can be closed again and the element thus behaves like a switch that can save its current state even without a power supply. And this is precisely what is required.

Recommended external content

We have selected external content from YouTube for you and would like to show it to you right here. To do this, you must reveal it with one click. You can hide the external content at any time with another click.

I agree to external content from YouTube being shown to me. This may result in personal data being transmitted to third-party platforms. You can find more information in our Privacy Policy.

However, the individual components have to be switched at different voltages up to now and are thus not suitable for use in the electronics sector. “We are now demonstrating how it is possible to develop components with less variability”, says Alff. Alff attributes this success to the cooperation with Molina-Luna. “I am delighted that we have two teams here in Darmstadt that complement each other so well for this type of research.” The group headed by Molina-Luna are investigating the components produced by Alff’s team using an electron microscope. This has allowed the researchers to identify the important role played by so-called grain boundaries. Each component consists of multiple tiny grains of crystal, just like a 3D mosaic. The discharges run along the boundary edges between the grains. Normally, there is not much order to the structure of the “mosaic”. The researchers thus deposit layers of hafnium oxide onto an electrode, whose crystal lattice had a particular orientation. The grain boundaries in the hafnium oxide took on this orientation and became much more ordered as a result, especially with respect to the shortest route between the switching contacts. The lightning bolts are thus offered a much clearer path and the switching voltage does not fluctuate as much.

As a next step, the group now aims to precisely determine the location where a grain boundary will grow so as to reduce the variability even further. “For this purpose, we want to give the base plate on which the crystals grow a defined structure”, says Alff. This could be a tiny groove along which the grains orientate themselves. If Alff and Molina-Luna continue to work so well together, they are sure to succeed.

Publication

Stefan Petzold, et al: Forming-Free Grain Boundary Engineered Hafnium Oxide Resistive Random Access Memory Devices, Adv. Electron. Mater. 5, 1900484 (2019)