Current topics

Motivation

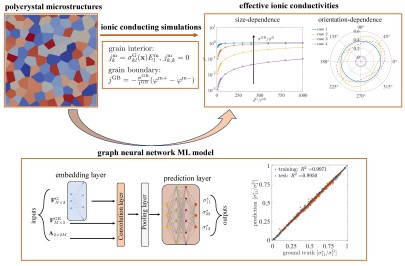

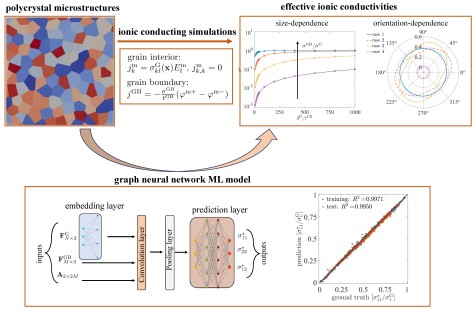

The multiscale nature of microstructured materials necessitates multiscale methods to characterize their physical properties. Data-driven/ML methods outperform conventional methods in terms of efficiency and effectiveness. This motivates us to adopt data-driven multiscale methods to investigate the multiphysical behavior and properties of various microstructured materials including paper materials, Lithium-ion batteries, porous structures, polycrystalline oxide ceramics, and strut-based lattice structures.

Methodology

- Microstructure generation and meshing

- Computational homogenization

- Finite Element simulations

- Machine Learning

Motivation

Machine learning-based microstructure-property relationship (MPR) modeling is crucial in materials science and engineering due to its ability to streamline material design processes. By offering a faster and more efficient alternative to traditional methods, machine learning accelerates the prediction of material properties based on microstructural features. Moreover, the MPR, constructed from physical simulations, can be utilized by non-expert communities. It serves as a valuable tool not only for professionals but also for those with limited expertise in the field. Additionally, the MPR is instrumental in sensitivity analysis, enabling researchers to determine the significance of various material features in shaping desired material properties.

Combining machine learning with modeling techniques such as FEM offers a powerful approach to generating data and building the MPR based on simulation data. By integrating machine learning algorithms with simulation models, researchers can effectively simulate a wide range of material configurations and conditions, generating extensive datasets that capture the complex interactions between microstructural features and material properties. These datasets serve as valuable inputs for training machine learning models, which can then extract patterns and correlations to establish the MPR.

Methodology

- Machine Learning

- FEM

- Versatile tools of codes for generating images or Representative Volume Elements (RVEs) across diverse microstructure designs

Motivation

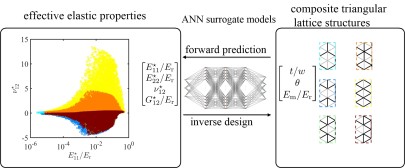

Achieving optimized and/or target effective properties in microstructured materials by tailoring microstructural features is of high practical interest. We demonstrate that this challenging task can be efficiently solved by data-driven method. We have realized the inverse design of effective elastic properties composite triangular lattice structures by ANN-based ML models. We also considered the microstructure optimization of electrode particle materials by incorporating the ML surrogate models into genetic algorithm optimization methods. We are working on the inverse design and optimization of other microstructured materials.

Methodology

- Microstructure generation and meshing

- Computational homogenization

- Finite Element simulations

- Machine Learning

- Optimization