Objective

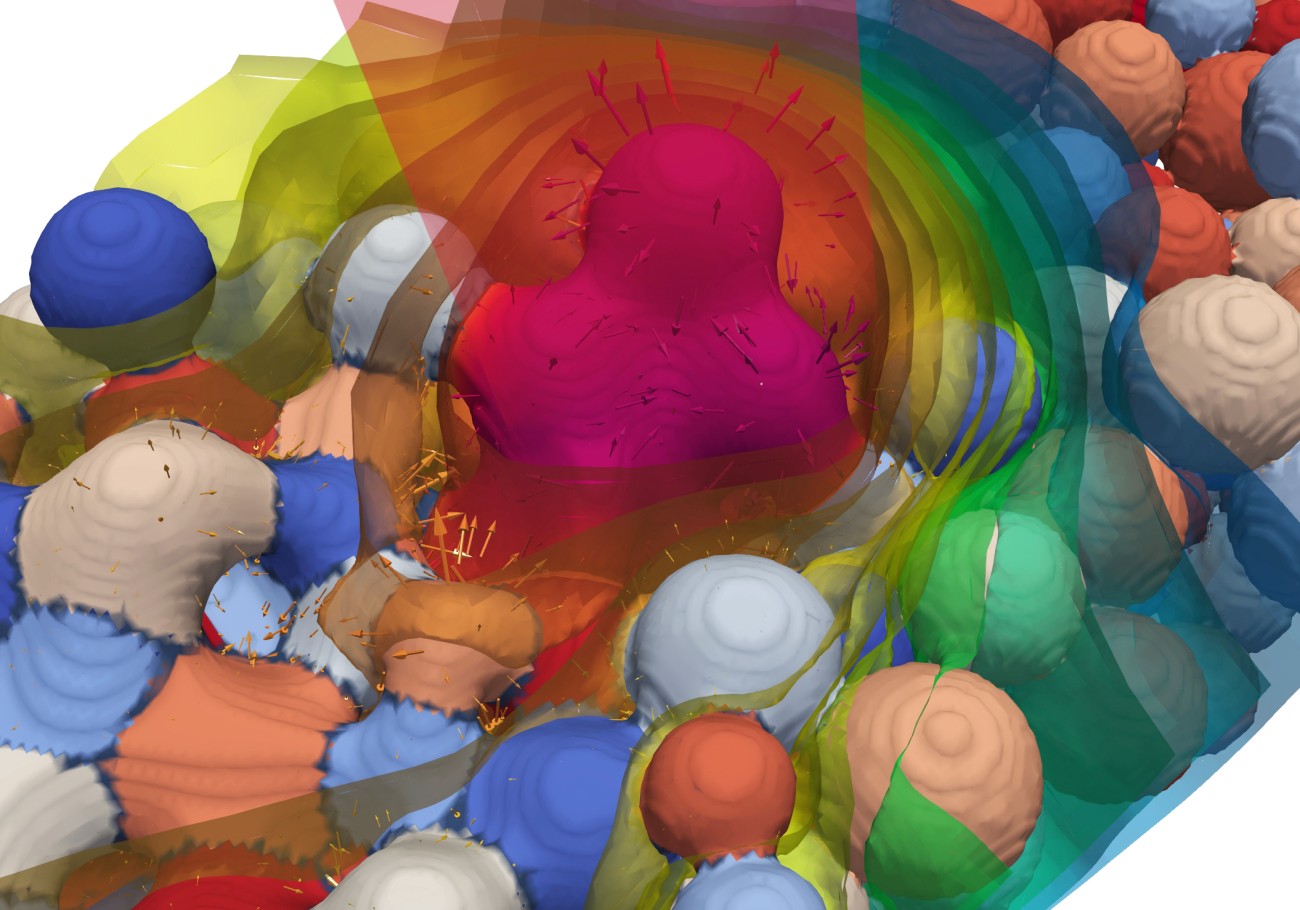

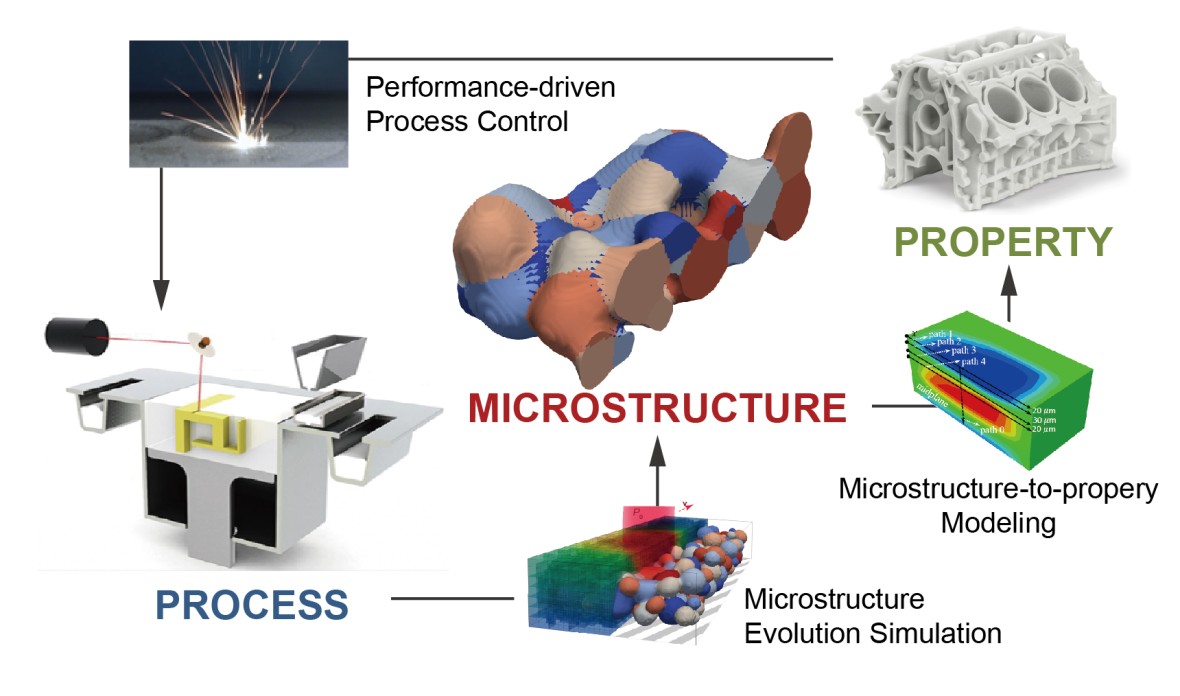

This research area aims to enrich the modeling and computational toolkit which is practicable for the simulation of advanced processing methods, and thereby provide transferable insights into the “Process-Microstructure-Property ” relations.

Methods

- Finite Element/Discrete Element Methods

- Non-equilibrium Thermodynamic Analysis

- Algorithm Investigations