3D-multilayer simulation of microstructure and mechanical properties of porous materials by selective sintering

New Publication in “GAMM-Mitteilungen”

2021/10/13

Authors: Xiandong Zhou, Yangyiwei Yang, Somnath Bharech, Binbin Lin, Joerg Schroeder and Bai-Xiang Xu

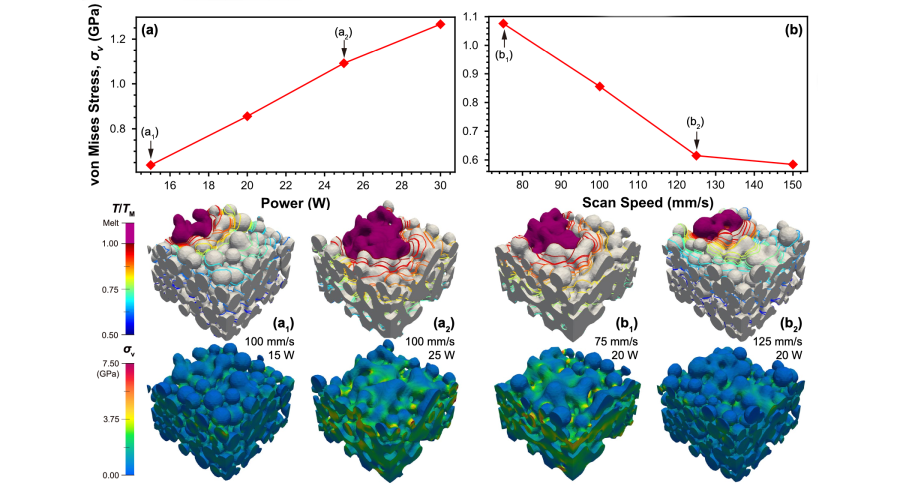

This work presents multilayer phase-field simulation of selective sintering process and the calculation of effective mechanical properties and residual stress of the microstructure using the finite element method. The dependence of the effective properties and residual stress on the process parameters, such as beam power and scan speed, are analyzed. Significant partial melting of powders is observed for large beam power and low scan speed, which results in low porosity of the microstructure. Nonlinear relationship between the effective mechanical properties and process parameters is observed. The increasing rate of effective mechanical properties decreases with increasing beam power, while increases with decreasing scan speed. The dependence of effective Young’s modulus and Poisson’s ratio on porosity are well established using power law models. Stress concentrations are found at the necking region of powders and the intensity increases with the level of partial melting, which results in increasing residual stress in the microstructure. The numerical results reveal quantitatively the process-microstructure-property relation, which implies the feasibility of the subsequent data-driven approach.