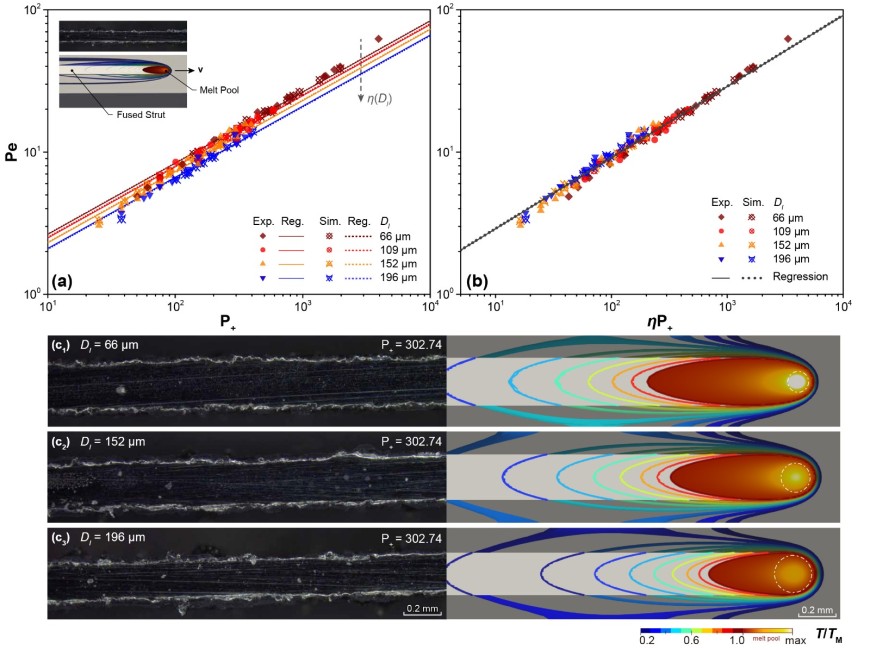

Validated Dimensionless Scaling Law for Melt Pool Width in Laser Powder Bed Fusion

New Publication in “Journal of Materials Processing Technology”

2021/08/04

Authors: Yangyiwei Yang, Alexander Grossmann, Patrick Kuehn, Jan Moelleney, Lorenz Kropholler, Christian Mittelstedt and Bai-Xiang Xu

The melting process during laser powder bed fusion (LPBF) is accompanied by complex physical phenomena, which can rarely be scaled with acceptable effort to utilize the melting process in component design to obtain tailored mechanical properties with adequate machine productivity. A constitutive law relating melt pool geometry to the process parameters thereby plays an essential role in practically fostering machine productivity and component quality in LPBF. In this work, we derive an enhanced dimensionless scaling law based on dimensional analysis to characterize the melt pool width, which is also capable in scaling the beam-size-dependent laser attenuation. Measurements from LPBF-produced specimens and 3D phenomenological LPBF finite element simulations are also performed in batch to validate the derived law. The regression analysis presents the correlation ∼ 97-98% for the simulated melt pool widths and ∼ 70-90% for experimental measured ones, with fabricated minimum strut thickness of 113 μm. After scaling the effective laser power with the calibrated laser attenuation, the proposed scaling law can be extended to be beam-size independent, as demonstrated by the regression of overall experimental measurements and simulation results, performed under different laser beam diameter, to the unified law with correlation ≥97%. It demonstrates the feasibility of proposed scaling law in melt pool controlled LPBF manufacturing for designing and producing thin-walled components with strut thicknesses in the micrometer range.