High-throughput computational homogenization of porous materials produced by selective laser sintering: a diffuse-interface–based workflow

New Publication in “Computational Mechanics”

2025/03/01

Authors: Yangyiwei Yang, Xiangfeng Li, Junlong Ma, Somnath Bharech, Xiandong Zhou, Xiang-Long Peng, Bai-Xiang Xu

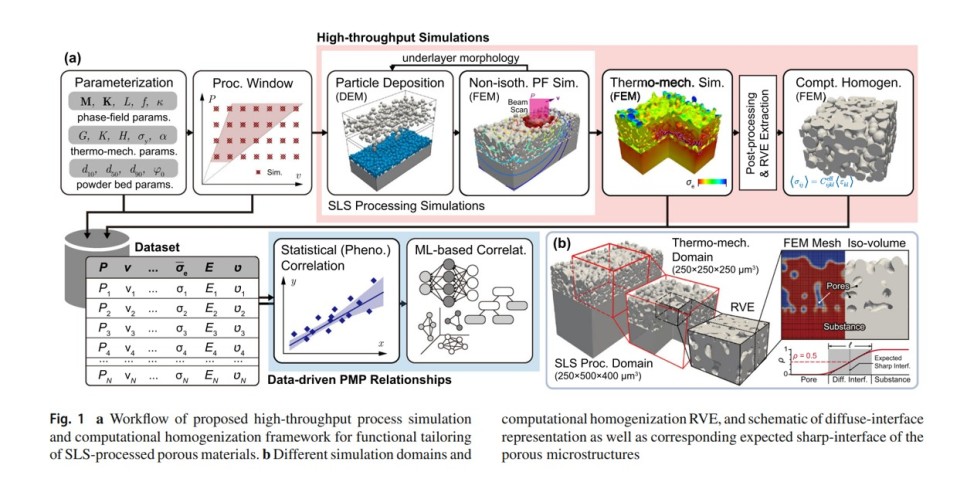

Increasing demand for porous materials necessitates continuous optimization and design of materials with further improved mechanical and functional properties. Advanced processing techniques like additive manufacturing offer promising perspectives to tailor the material properties on the microstructure level, attributed to their unique thermal conditions. It relies, however, strongly on the understanding of the process-microstructure–property relationships. This is challenging for purely empirical experimental investigations due to low time and cost efficiency and thus limited data. In this paper, we present a workflow of high-fidelity simulations arranged from in-process microstructure evolution to microstructure-based property evaluation. Various porous microstructures were obtained by multiphysics phase-field simulations under varying process parameters for the selective laser sintering of 316 L stainless steel powder beds. Subsequently, and directly benefiting from the phase-field interpretation of the microstructure, diffuse-interface–based computational homogenization was performed to evaluate the effective elastic properties of all simulated cases. In particular, we implemented and examined various interpolation schemes of the local mechanical properties across the interfaces. By using the framework, batched elasticity evaluation on SLS-processed four-layer porous microstructures was performed in a certain processing window, delivering sufficient data to establish the process-microstructure–property relationships presented by regression models.

Link to Article

Computational Mechanics, Published: 01 March 2025