Multiphysics simulations of microstructure influence on hysteresis and eddy current losses of electrical steel

New Preprint on “arXiv”

2025/02/03

Authors: Patrick Kühn, Yangyiwei Yang, Guanyu Chen, Shanelle N. Foster, Herbert Egger, Bai-Xiang Xu

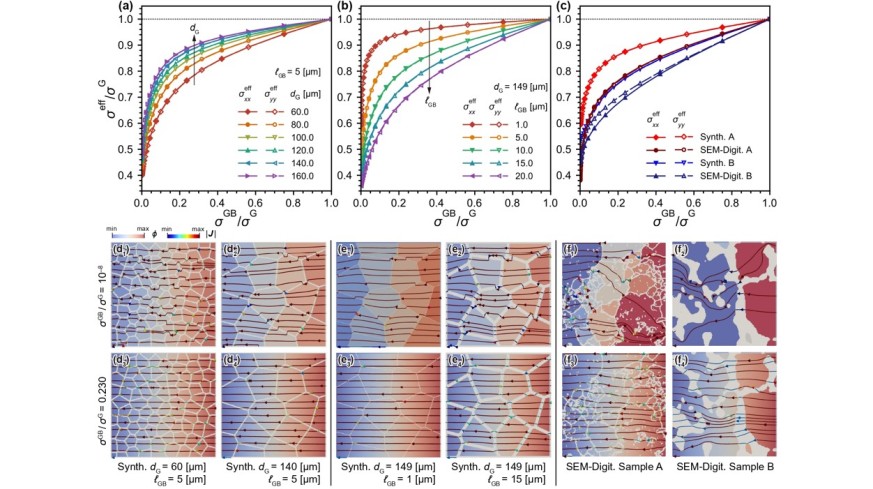

Improving efficiency of electrical machines requires fundamental knowledge on the mechanisms behind magnetic and eddy current losses of the magnetic core materials, with Fe-Si alloy as a prototype. These losses are intrinsically influenced by the microstructure of the materials. This necessitates physics-based, microstructure-informed multiscale simulations. In the present paper, we utilised micromagnetic simulations and computational homogenization methods to calculate the effective hysteresis and effective conductivities of Fe-Si electrical steels. To demonstrate the methodology, binder-jet printed electrical steel material samples with different microstructure were investigated. The microstructure samples were digitized based on both the descriptor-based synthetic reconstruction and SEM-image-based digitization. More samples were generated with varying microstructure features such as grain size and grain boundary phases. The micromagnetic simulations were then performed to investigate the magnetic hysteresis and hysteresis loss. The eddy current loss was also evaluated by using the effective conductivity through computational homogenization. By performing parameter research on a series of synthetic microstructures, effects of average grain size and grain boundary (GB) phase thickness on the hysteresis loss and eddy current loss were unveiled. An average grain size around 120 µm has the lowest hysteresis loss, although the eddy current loss increases with the grain size. Increasing GB-phase thickness helps reduce both losses. Results indicate the potential to decrease loss of magnetic core materials by microstructure optimization.