Ion track membranes and nano materials

In order to manufacture these membranes polymer foils (PC, PET, PI etc.) are irradiated with heavy ions which penetrate the polymer and leave cylindrical damage zones along their tracks. These areas can be removed selectively by chemical etching. By varying the etching conditions, both size and shape of the resulting pores or channels can be controlled.

Metallic nanowires and -tubes

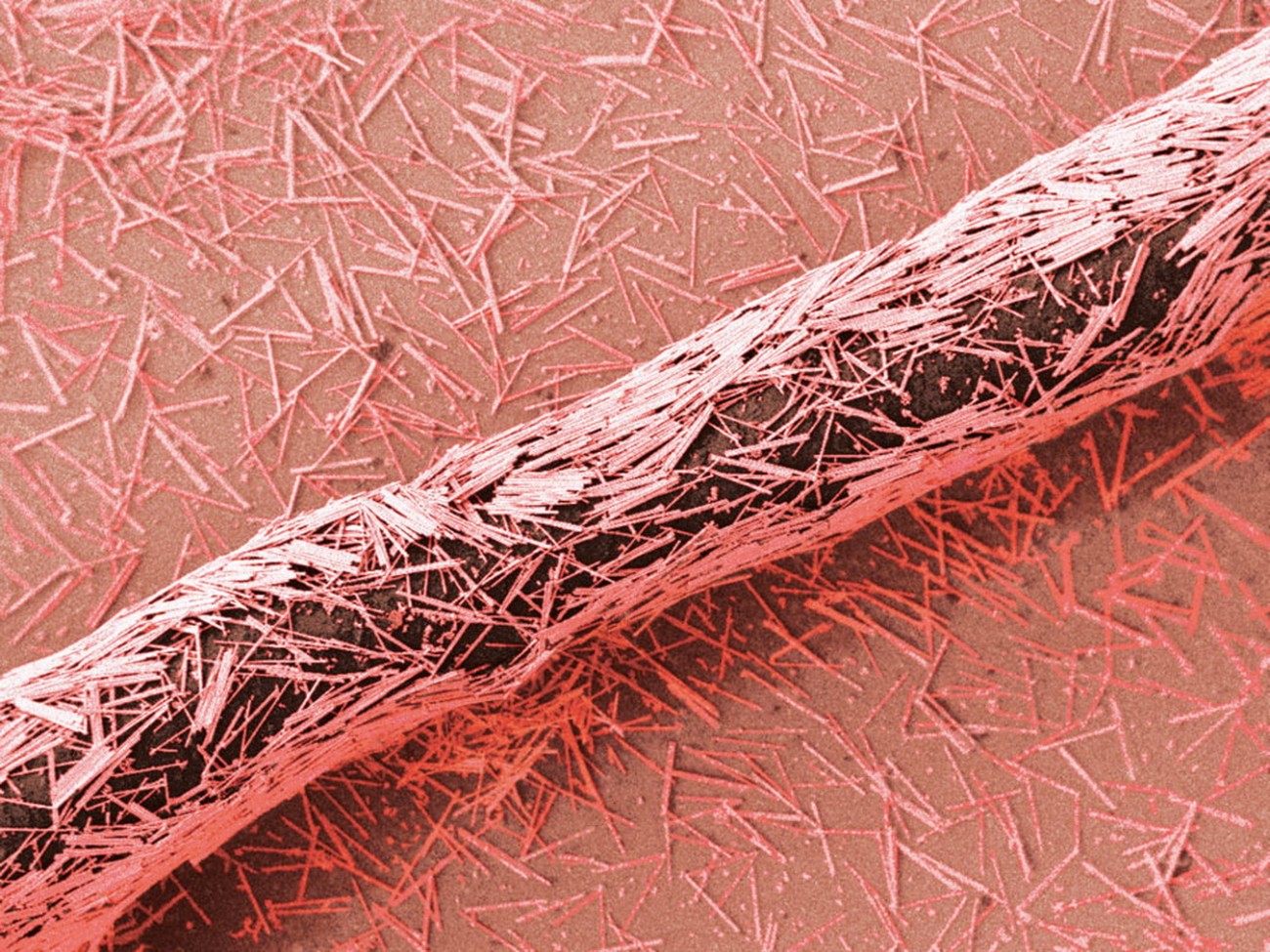

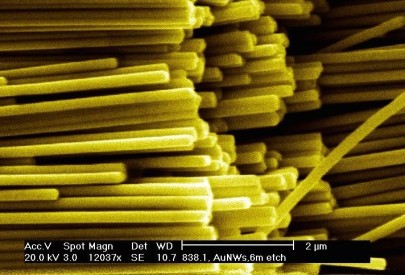

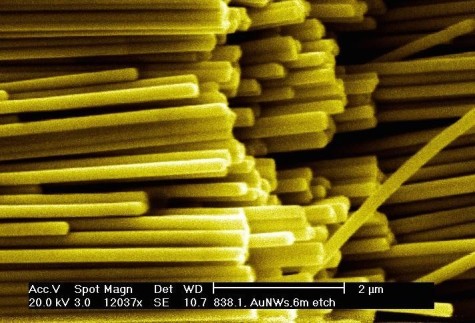

In a further process step the nanochannels are filled electrochemically with metals (Cu, Pt, Au etc.) yielding nanowires, which can be freed by dissolution of the polymer template. Besides morphological parameters such as surface topography, microstructure and crystallinity, physical properties like electrical conductivity and thermal stability are investigated. The wires disintegrate upon heating considerably below the melting point of the bulk material, forming a row of spheres (Rayleigh instability), an effect that is explored in detail.

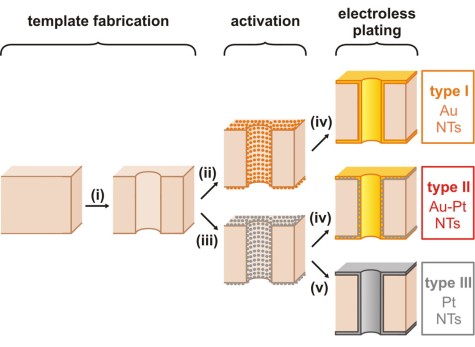

Metal structures can also be obtained by an electroless approach. To generate surface selectivity the polymeric membrane is covered with metallic nanoparticles as a first step. In the subsequent autocatalytic redox reaction of a metal complex and a reducing agent, the initial particles act as nuclei for the metal deposition. Depending on the reaction conditions, polycrystalline wires or tubes are obtained.

Nanotubes exhibit exceptional physical and chemical properties, e.g. plasmon resonance or an considerably enhanced catalytic activity compared to bulk material. Main research areas are the control of morphological parameters, the correlation of structure and properties and the utilization of this knowledge in further experiments. Possible applications include catalysis, separation or sensor technology.

Oxidic nanowires and –tubes, thin films

Alternatively the ion track etched templates are filled with metal oxides by different means with a focus on functional materials (e.g. semiconducting or magnetic oxides), whose properties qualify them for applications in electro analysis, heterogeneous catalysis or photonics. Like the other nanostructures, they are mainly characterised by SEM, TEM and XRD as well as specific experiments.

Sulf-supported and hybrid nano-architectures

When low-dimensional metal nanostructures are used as individual nano-objects, they are difficult to handle and organize because rather mobile (which has implications regarding their release), and, due to their tiny size, limited in the strength they interact with their environment.

By combining hundreds of millions up to billions of such building blocks into free-standing 3D architectures, we augment the advantages of the individual nanostructures with those of an ordered superstructure, which provides mechanical robustness, a high nanostructure density, percolating conduction paths, high porosity, efficient diffusive access, and greatly simplifies macroscale handling. For instance, interconnected and free-standing networks composed of metal nanowires or nanotubes can be employed as highly active and durable catalysts, or as fast-responding, sensitive and selective sensors.

In this context, we use ion-track technology to design template membranes for the deposition of complex 3D nano-architectures. Moving beyond structural design, we also expand the compositional range of our synthetic processes. While the areal density, alignment, size and general shape of our nanoscale building blocks can be precisely defined by the template fabrication conditions, the choice of the applied deposition or modification reaction controls the composition and nanostructure of the products. Combined, both aspects open up a huge parameter space for optimizing the nanomaterial properties.

We also explore synthetic concepts based on symmetry breaking and directed crystal growth for directly growing anisotropic nanostructures on various surfaces, without the need for templating steps. While such nanostructures tend to be more random in nature, their production is straightforward and easy to scale. While such reactions do not rely on templates, we also combine them with our templating strategies to further increase the structural complexity of our products.