Plasma Immersion

Two vacuum chambers are available for PIII&D. One of those chambers offers the possibility to combine magnetron sputtering with the plasma process.

The samples are fixed on a plate (usually with screws) that is supported by an insulator in the inside of the chamber. The voltage is applied via a high voltage feedthrough. Two high voltage pulsers and one DC power supply can be connected.

For characterization purposes a quadrupole mass spectrometer and an optical spectrometer are available.

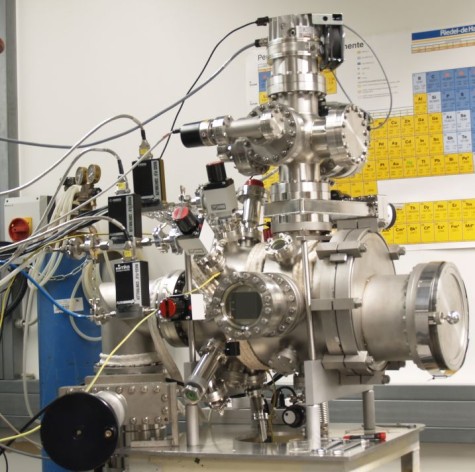

Chamber 1

for implantation and preparation of DLC films

- Volume: 0.075 m3

- Base pressure: 10-7 hPa

- Diameter sample holder: 10 cm

- Number of MFCs: 4

High voltage pulser

- Max. voltage: 25 kV

- Pulse length: 1-100 µs

- Pulse rise time: 300 ns

DC power supply

- Max. voltage: 3.5 kV

- max. current: 1.5 A

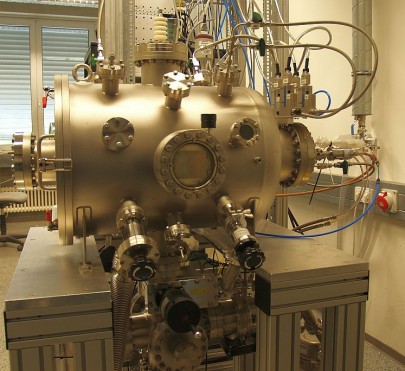

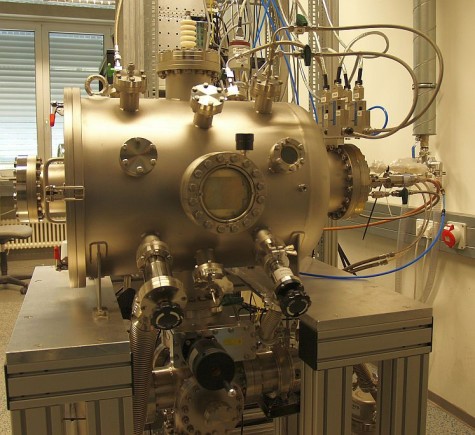

Chamber 2

for the preparation of DLC and metal films

- Volume: 0.065 m3

- Base pressure: 2 x 10-7 hPa

- Diameter sample holder: 10-20 cm

- Number of MFCs: 4

Sputter source

- Target diameter: 2 in. (5,1 cm)

- Flexible head and positioning

- Integrated shutter

- Power supply: 300 W RF

Chemical Solution Deposition

Dip coating

Eigenbau Dipcoater

Precisely working dipping device for sample coatings. Parameters such as dipping depth and speed as well as number of cycles are adjustable.

The instrument is home-made, with high repeatability, flexible sample fixation, software control and the following specs:

- Max. distance: 150 mm

- Vertical motion speed: 0.1-0.9 mm/min

- Max. sample weight: 200 g

- Computer control: USB