For the use of functional materials in AM powder materials are required. Since there are no functional material powders designed for AM commercially available, it is of high interest to develop processes for the powder production in a laboratory scale.

Targeted metal powders are permanent magnets based on RE-3d-metal compositions (Nd2Fe14B, Sm-Co) and La-Fe-Si or Heusler based materials for magnetocaloric applications.

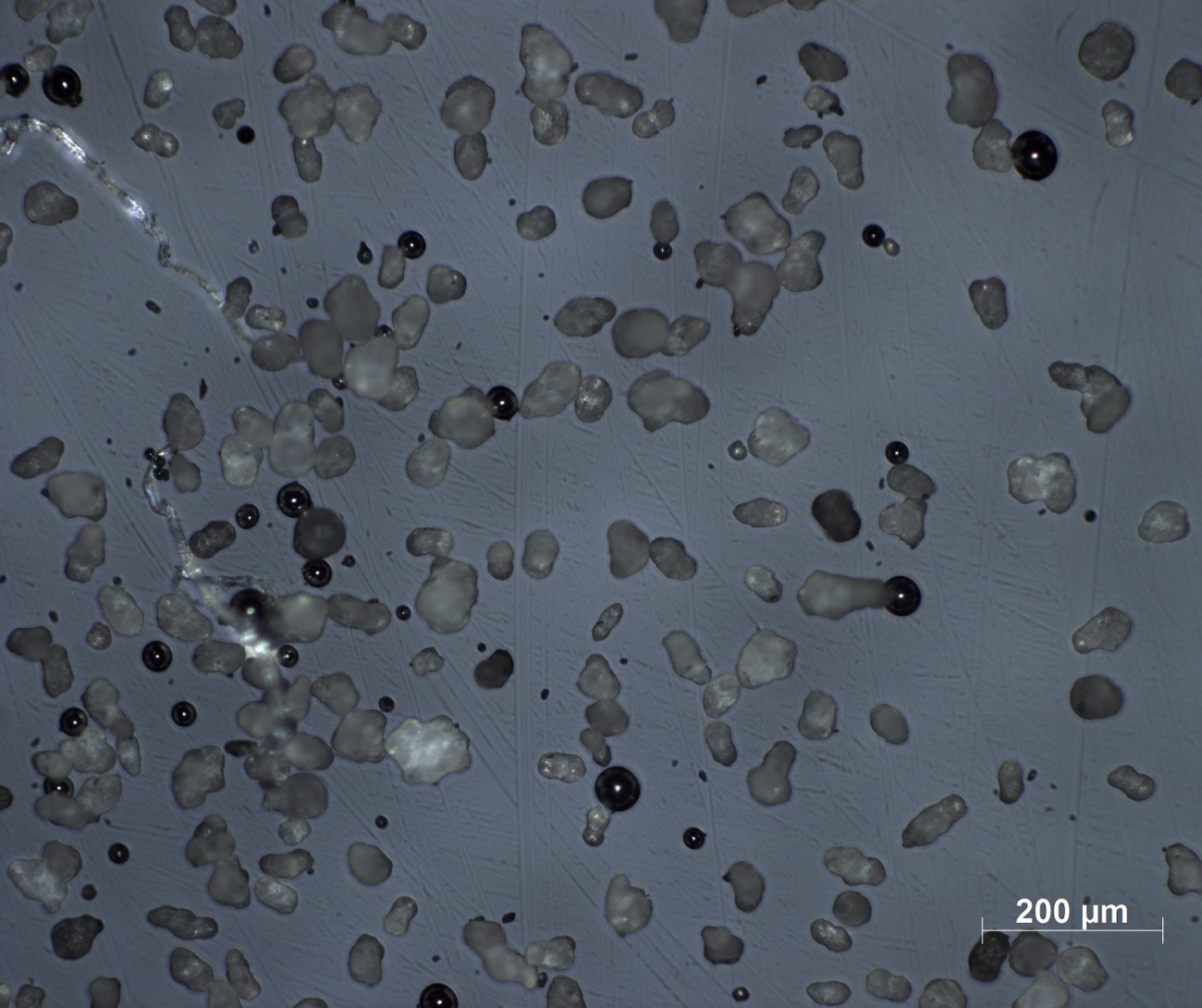

Spherical powders can be achieved by Gas Atomization (Melt flows in gas stream through a nozzle) and/or plasma spherodization (irregular shaped powder particles stream through an inductively couple plasma and get partially molten and surface smoothened). The particle size distribution has to be adapted for the different AM processes – for Laser-powder bed fusion average sizes of 40µm are targeted.

Safe powder handling and avoiding oxidation are mandatory. Small sized particles of a few micrometers size oxidize rapidly in air and start to burn, thus a safe transfer has to be developed for application.

In the project 3DREMAG (funded by EIT Raw Materials, homepage link: http://3dremag.eu) a process route for Nd-Fe-B powders is set up and upscaled to industrial production.

Available characterization methods: Powdersizer (Laser diffraction), SEM (EDX), XRD