Diffusion behavior of heavy rare-earths for grain boundary engineering of sintered Nd-Fe-B-based permanent magnets produced by the 2-powder method

New publication in Acta Materialia

2024/04/22

K. Opelt, C.-C. Lin, M. Schönfeldt, J. Gassmann, S. Yoon, O. Gutfleisch

Acta Materialia 270,119871 (2024).

DOI: 10.1016/j.actamat.2024.119871

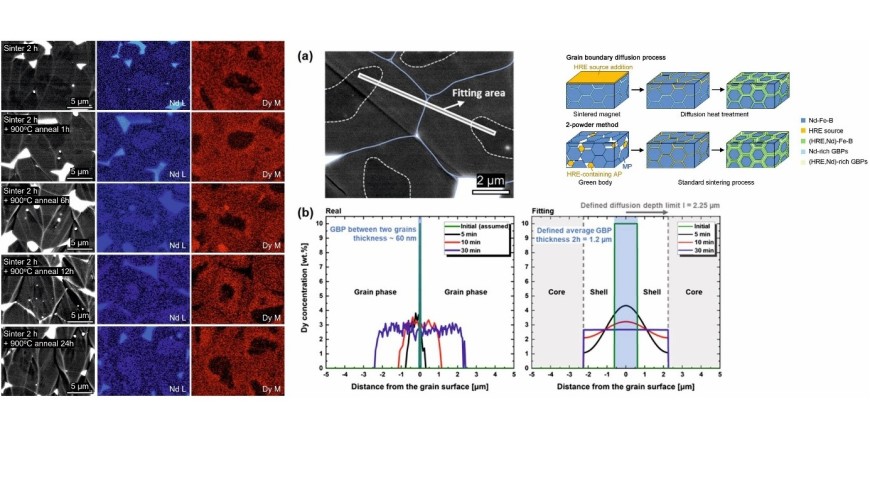

The 2-powder method (2PM) for the production of high-performance Nd2Fe14B-based sintered magnets consists of blending a coarser heavy rare-earth (HRE) free main phase powder (here D50 = 5.3 μm) and a finer HRE-containing high anisotropy powder (here D50 = 2.6 μm) of Dy content of 10 wt.%. The development of the core-shell structure for different sintering conditions, was investigated and the diffusion coefficient for the heavy rare-earth element dysprosium of D = (1.83 ± 0.54) x 10-11 cm2/s was determined. Magnets containing 0, 1, 2, and 3 wt.% Dy were produced by the 2PM and a constant coercivity gain of around 120 kA/m per added Dy contents was reached without a significant decrease in remanence. Finally, the 2PM was compared with the conventional powder metallurgical production process. The enormous potential for decreasing the amount of critical HREs in Nd-Fe-B–based sintered magnets is demonstrated, especially in large volume magnets as 2PM is not restricted to 5 mm thick pieces, but can be applied to any size of magnet.

Find the open access article here.